3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Do you have any kind of ABL (BLtouch, etc?). If so what does the bed mesh look like.

Edit: I should learn to read better. No ABL.

It may be worth looking at leveling (tramming) your bed.

Basically tighten each of your screws all the way and then loosen them 1 and a half full turns counter clockwise.

Let’s start with your rear left screw. It’s the one with the bed wire retainer and so it doesn’t have as much room to adjust as the others.

In the next steps we’re not going to loosen or tighten this one any more than what we just did. We’re going to use it as the reference/base point for the other 3.

Home the printer and then using the controls on the LCD (or via octoprint/Klipper if you have them) bring your nozzle over the spot where the screw is. Then baby step it down to doing the paper test until you just start to feel the nozzle grab the paper.

Once you have that lift your nozzle up 5mm and move it over the front right screw. Then lower your nozzle 5mm (you can do this in 1mm increments 5 times just to be sure it isn’t likely to crash into the bed. You can tighten the screw if you need room). Once you’re down the 5mm the nozzle will be at the same height as the reference screw.

Do the paper test here and adjust the screw beneath it until it just grabs.

Now do the same for the front left and rear right screws. Each time you’re using your nozzle controlled by the steppers. Which means when it’s moved up by 5 and then down by 5 you’re at the same height.

Once you’ve done all 4 home your printer again and then repeat it. Again starting with the rear left (reference) screw.

We’re doing this because when you tighten and loosen corners the others pivot relatively like a large patch of ice floating on water. Stepping towards one edge raises others. It’s why we’re doing them in opposing diagonal pairs.

(Rear-left and front-right) (Front-left and rear-right)

Once you have all 4 trammed you’ll home again and then check the center of the bed with the paper test. Hopefully it’s the same but these ender beds can curve inward or bulge out a little bit. If so there’s a few ways to fix it but let’s start with the tramming which may solve your issue.

It was leveled pre-printing and with a heated bed. Could still be a level issue because I don’t have ABL but I’m not a noice to leveling.

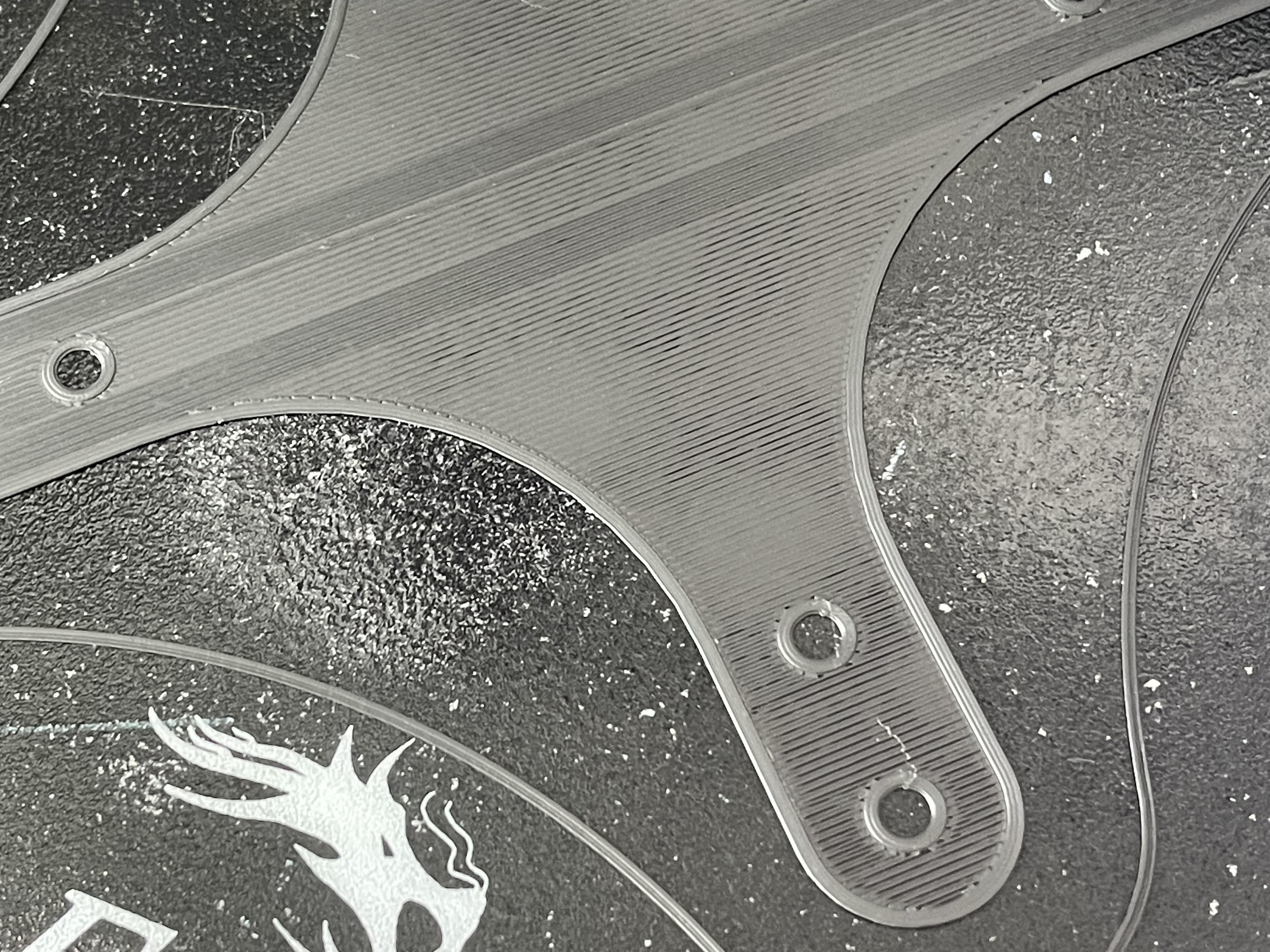

Print came out great regardless. Also, not my model.

Same amount of grab to the paper in the center? Wondering if it’s warped? That was such a huge pain for me with mine.

Yep. I’ve got some gcode that automates it. Nice grab dead center and in each corner.

Ahh. May be physical then. I do have a longer write up I did for somebody else who was having issues who was running Klipper I can link to shortly.

But basically it may be worth making sure everything is solid physically. E.g. extrusions are square, not overly tightened, vwheels are tight enough without being so tight that they end up having bumps and presenting weird issues like this.

Here’s the link. Nothing more frustrating than when everything should work and just isn’t. Been there so many times myself.

https://lemmy.world/comment/7904011

Something else to check… print a small calibration cube. Because I’m wondering if you’re getting consistent extrusion. Inconsistent extrusion along the same plane and height on the cube will be pretty obvious.